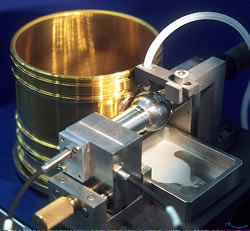

Abrasion tester

An example of an abrasion tester

The abrasion tester usually consists of a rotating sphere that is loaded onto the sample or component using a dead weight. An abrasive silicon carbide based slurry is dripped onto the wear interface throughout the abrasive wear test. The amount of abrasive wear is measured optically after the test is complete in a similar manner to that used in the Calo test / ball cratering. Simple to use software is used to calculate the coating abrasive specific wear rate. The abrasion tester can be used to measure the abrasive specific wear rate of coatings deposited on test samples and actual components.

Possible correlation between abrasion test results and cutting tool life

Some authors have speculated that there is a correlation between the abrasive wear measured on PVD coatings using an abrasion tester with the performance of PVD coatings on cutting tools. It should be stated though that the failure of coatings on cutting tools is a complicated phenomenon and abrasion resistance is only one of the properties that PVD coatings on cutting tools should exhibit. Although as the machining of abrasive materials such as carbon fibre becomes more widespread abrasive wear tests will become more common

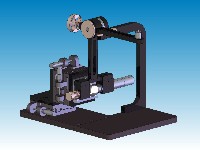

An alternative abrasive wear tester design

|