Anti-reflective optical [relevant-to-adsense type=”start”]thin film coatings[relevant-to-adsense type=”stop”] – every colour of the rainbow

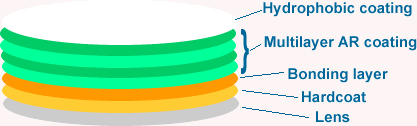

An example of the structure of a modern anti-reflection optical coating is shown below. The anti-reflection optical coating is actually a simple interference filter albeit on the micro scale. The colour and intensity of the residual reflection observed can be changed by altering the number of layers, the thicknesses of the layers and the refractive index of each layer. By controlling these factors the reflection colour of the optical coating can be changed to every colour of the rainbow and a few more besides. Mirror optical coatings for sunglasses are designed using the same method.

Anti-reflective optical coatings on plastic

Plastic substrates such as CR39, polycarbonate can be coated with these optical coatings but they must be coated with a hard coating first. The hard coating is usually a thermally cured polysiloxane. A thin (~5nm) hydrophobic coating is finally deposited on the surface to enable easier cleaning.

An example of an anti-reflective optical coating on a plastic lens. The thicknesses of the different optical layers is not shown, in reality the hard coating (3 to 5 microns) is actually much thicker than the total thickness of the multilayer antireflective coating (0.2 to 0.3 microns). The hydrophobic coating is only 5nm thick.

Spectrally stable optical coating

Anti-reflective optical coatings deposited using magnetron sputtering are extremely dense, which results in good spectral stability so the reflected colour does not change over time.

Dense and hard optical coatings

The density and hardness of the optical coatings also improves scratch resistance and durability.