This website concentrates on the PVD vacuum surface coating technique magnetron sputtering as this is the most widely used PVD [relevant-to-adsense type=”start”]thin film coating[relevant-to-adsense type=”stop”] technique as it is suitable for that is many applications. However the basics of arc evaporation and pulsed laser ablation can be viewed by clicking the links.

What is the surface coating technique magnetron sputtering?

Magnetron sputtering is an extremely flexible coating technique that can be used to coat virtually any material. Sputtering is basically the removal of atomised material from a solid by energetic bombardment of its surface layers by ions or neutral particles.

Magnetron sputtering – A vacuum coating process

Prior to the sputtering coating process a vacuum of less than one ten millionth of an atmosphere must be achieved. Once the appropriate pressure has been reached a controlled flow of an inert gas such as argon is introduced. This raises the pressure to the minimum needed to operate the magnetrons, although it is still only a few ten thousandth of atmospheric pressure.

Magnetron sputtering – The sputtering process

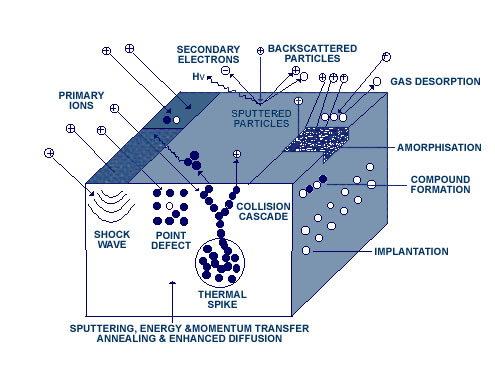

When power is supplied to a magnetron a negative voltage of typically -300V or more is applied to the target. This negative voltage attracts positive ions to the target surface at speed. Generally when a positive ion collides with atoms at the surface of a solid an energy transfer occurs. If the energy transferred to a lattice site is greater than the binding energy, primary recoil atoms can be created which can collide with other atoms and distribute their energy via collision cascades. A surface atom becomes sputtered if the energy transferred to it normal to the surface is larger than about 3 times the surface binding energy (approximately equal to the heat of sublimation).

The sputtering of a target atom

Magnetron sputtering – Sputtering is only one result of ion bombardment

Sputtering of a target atom is just one of the possible results of ion bombardment of a surface. The other possibilities are summarised below. Aside from sputtering the second important process is the emission of secondary electrons from the target surface. These secondary electrons enable the glow discharge to be sustained.

Magnetron sputtering – Almost no restriction on target material

The sputter process has almost no restrictions in the target materials, ranging from pure metals where a d.c.-power supply can be used to semiconductors and isolators which require a r.f.-power supply or pulsed dc. Deposition can be carried out in either non reactive (inert gas only) or reactive (inert & reactive gas) discharges with single or multi-elemental targets.

Magnetron sputtering – Magnets enable lower pressures to be used

During the sputter process a magnetic field can be used to trap secondary electrons close to the target. The electrons follow helical paths around the magnetic field lines undergoing more ionizing collisions with neutral gaseous near the target than would otherwise occur. This enhances the ionisation of the plasma near the target leading to a higher sputter rate. It also means that the plasma can be sustained at a lower pressure. The sputtered atoms are neutrally charged and so are unaffected by the magnetic trap.

The movement of an electron around a magnetic field line

The technical name for this vital invention is the magnetron. Click magnetron to learn more.

To find out how coatings grow on a surface click nucleation and growth.